- Application

- For Concrete For Stone For Dekton/Ceramic For Glass Others

- For Stone

- Flexible Polishing Pad Diamond Hand Pad Diamond Flexible Sheet Diamond Belt Diamond Flap Disc Diamond Cup Wheel Diamond Grinding Disc Diamond Fickert Diamond Cutting Blade Diamond Wire Saw Diamond Wire Diamond Finger Bit Diamond Drum Wheel Diamond Profiling Wheel Diamond Drill Bit Small Tool Other Diamond Edge Polishing Pad Calibrating Wheel

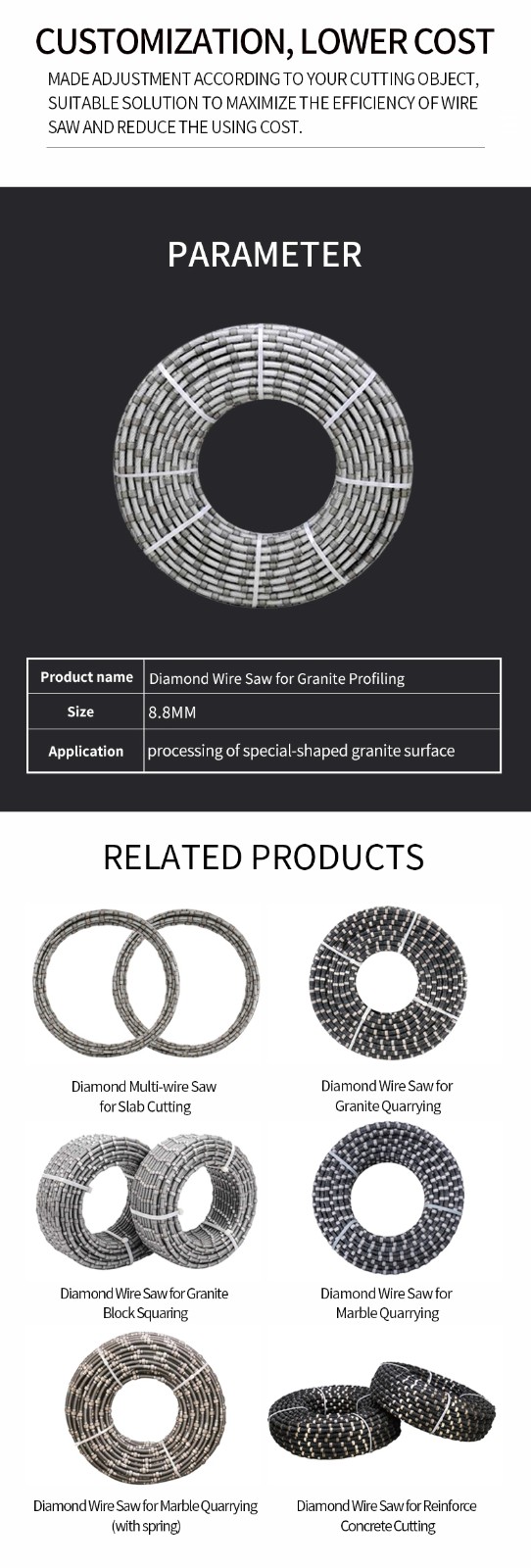

Diamond Wire Saw for Granite Profiling

Unique technology, excellent performance, cost effective, suitable for processing of special-shaped granite surface.

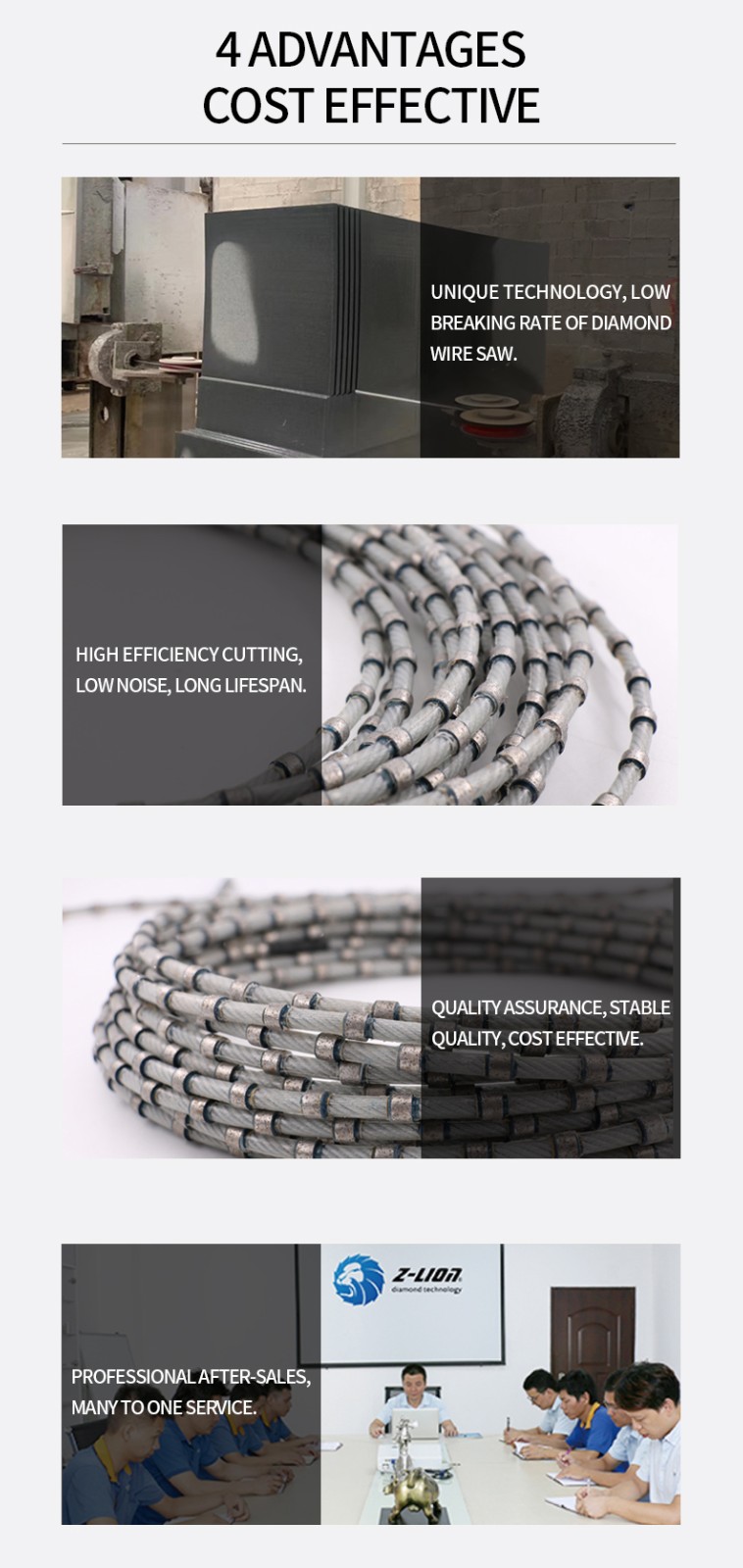

Advantage:

1. Unique technology, low breaking rate of diamond wire saw

2. High efficiency cutting, low noise, long lifespan

3. Quality assurance, stable quality, cost effective

4. Professional after-sales, many to one service

Product Name: Diamond Wire Saw for Granite Profiling

Specification:8.8mm

Expert Guide: Understanding Granite Wire Saws

Introduction

Welcome to our expert guide on understanding granite wire saws. In this article, we will delve into the world of granite wire saws, exploring their advantages, components and technology, applications, and tips for choosing the right one and maintaining it for optimal performance and safety.

Granite wire saws have revolutionized the mining and cutting of natural stone, such as granite, by replacing traditional manual methods with advanced technology. These machines offer numerous benefits, including high yield, fast mining speed, and enhanced safety and environmental considerations.

In this comprehensive guide, we will explore the various components and technologies that make granite wire saws stand out in terms of performance and efficiency. From well-known brand inverters and PLCs to permanent magnet motors and diamond wire, we will uncover the secrets behind their excellent cutting efficiency and stability.

Furthermore, we will discuss the diverse applications of granite wire saws, from sawing large stone blocks into slabs to performing straight cuts, arc cuts, and other specialized cuts. We will also touch upon the compatibility of granite wire saws with different types of stone, such as marble, limestone, and sandstone.

Choosing the right granite wire saw can be a daunting task, but fear not. We will provide you with expert tips and insights to help you make an informed decision based on your specific needs and requirements. Additionally, we will share valuable maintenance and safety tips to ensure the longevity and optimal performance of your granite wire saw.

So, whether you are a professional in the stone quarrying industry or simply a curious enthusiast, join us on this journey as we unravel the world of granite wire saws and equip you with the knowledge to make the most out of this cutting-edge technology.

The Advantages of Granite Wire Saws

Granite wire saws offer a range of advantages that make them the preferred choice for cutting and mining granite. With their advanced technology and innovative design, these wire saws have revolutionized the stone quarrying industry. Here are some key advantages of using granite wire saws:

High Yield and Fast Mining Speed: Unlike traditional manual mining and blasting methods, granite wire saws ensure high yield and fast mining speed. These machines are equipped with diamond wire saws of different diameters and lengths, allowing for large cuts with minimal kerfs. This not only increases productivity but also reduces material wastage.

Efficiency and Precision: Granite wire saws are known for their efficiency and precision. With their CNC control systems and automatic work programs, these machines can perform straight cuts, arc cuts, and diversified cuts with ease. This level of precision ensures accurate and consistent results, saving both time and resources.

Safety and Environment: Granite wire saws prioritize safety and environmental concerns. They are equipped with complete protection functions and spare speed control interfaces to ensure safe operation. Additionally, these machines use diamond wire cutting technology, which is known for its low noise, low vibration, and minimal dust generation. This not only creates a safer working environment but also reduces the impact on the surrounding ecosystem.

Versatility: Granite wire saws are not limited to cutting granite alone. They can also be used to cut marble, limestone, sandstone, and other types of stone. This versatility makes them a valuable tool for various applications in the construction and architectural industries.

Durability and Reliability: Designed with premium equipment components and advanced technology, granite wire saws are built to last. They feature well-known brand inverters and PLCs, ensuring high stability and low failure rates. Moreover, the use of permanent magnet motors enhances cutting efficiency and ensures stable operation, even in demanding conditions.

In conclusion, granite wire saws offer a range of advantages that make them indispensable in the stone quarrying industry. Their high yield, fast mining speed, efficiency, precision, safety features, versatility, and durability make them the go-to choice for professionals in the field. Whether it's cutting granite or other types of stone, these wire saws deliver exceptional performance and reliable results.

Components and Technology

When it comes to granite wire saws, the components and technology used play a crucial role in ensuring optimal performance and efficiency. These machines are equipped with premium equipment components, including well-known brand inverters and PLCs. The combination of these components with original full digital communication technology and full current automatic tracking guarantees high stability and a low failure rate.

One of the key features of granite wire saw machines is their use of a permanent magnet motor. This motor not only ensures stable operation but also significantly improves cutting efficiency. In fact, when paired with Huada diamond wire, the cutting efficiency is boosted by more than 25% compared to standard equipment.

In terms of operation, granite wire saw machines are designed to be simple and easy to use. They offer automatic cutting capabilities and can be controlled wirelessly through a remote control. This allows for convenient and efficient operation, saving both time and effort.

Safety is of utmost importance in any cutting operation, and granite wire saw machines prioritize this aspect. These machines are equipped with a spare speed control interface and complete protection functions to ensure safe operation. This includes measures to prevent accidents and protect operators from potential hazards.

In conclusion, the components and technology used in granite wire saw machines are essential for their performance and efficiency. With premium equipment components, a permanent magnet motor, and user-friendly operation, these machines offer a reliable and safe solution for granite cutting.

Applications of Granite Wire Saws

Granite wire saws are versatile and efficient cutting tools that find numerous applications in various industries. The unique capabilities of these wire saws make them indispensable for specific cutting needs where traditional methods fall short. Let's explore some of the key applications of granite wire saws:

Quarrying and Mining: Granite wire saws are widely used in the mining industry for extracting large blocks of granite from quarries. With their high yield and fast mining speed, these wire saws offer a safe and efficient solution for granite extraction.

Architectural Decoration: Granite is a popular choice for architectural decoration due to its durability and aesthetic appeal. Granite wire saws are used to cut granite slabs into precise shapes and sizes, allowing for the creation of stunning architectural features such as countertops, flooring, and wall cladding.

Construction and Infrastructure: Granite wire saws play a crucial role in the construction and infrastructure sectors. They are used for cutting granite blocks into various structural components, including bridge decks, motorway aprons, and bridge abutments. The ability to cut in any direction, including curves and circles, makes wire saws ideal for complex construction projects.

Stone Fabrication: Granite wire saws are essential tools in stone fabrication workshops. They enable precise cutting of granite slabs into custom shapes and sizes, catering to the specific requirements of individual projects. From kitchen countertops to intricate sculptures, wire saws ensure clean and accurate cuts with minimal waste.

Repair and Restoration: Granite wire saws are also used in the repair and restoration of granite structures. Whether it's removing damaged sections or cutting new pieces to match existing ones, wire saws provide the precision and flexibility required for seamless repairs.

By harnessing the power of advanced technology and CNC control systems, granite wire saws offer unparalleled cutting performance and efficiency. Their ability to accept CAD files and program automatically allows for intricate and diversified cuts, making them indispensable tools in the stone industry.

When choosing a granite wire saw, it is essential to consider factors such as cutting efficiency, stability, and safety features. Regular maintenance and adherence to safety guidelines ensure optimal performance and longevity of the wire saw.

In conclusion, granite wire saws have revolutionized the stone industry with their ability to cut through granite and other hard materials with precision and speed. From quarrying to architectural decoration, these versatile tools have become an integral part of various applications, enabling the creation of stunning and durable granite structures.

Choosing the Right Granite Wire Saw

When it comes to choosing the right granite wire saw, there are several factors to consider. The right equipment can make a significant difference in the efficiency and effectiveness of your granite cutting operations. Here are some key considerations to keep in mind:

Cutting Efficiency: Look for a wire saw that offers high cutting efficiency. This will ensure that you can achieve fast and accurate cuts, saving you time and resources. Consider equipment with advanced technology, such as CNC control systems, which allow for automatic and precise cutting.

Wire Quality: The quality of the diamond wire is crucial for optimal performance. Look for wire saws that use high-quality diamond wire, as this will ensure durability and longevity. Huada diamond wire, for example, has been proven to improve cutting efficiency by over 25% compared to standard equipment.

Versatility: Consider the versatility of the wire saw. Look for equipment that can handle various types of stones, including marble, limestone, sandstone, and more. This will allow you to expand your cutting capabilities and cater to different customer needs.

Safety Features: Safety should always be a top priority. Choose a wire saw that comes with complete protection functions and spare speed control interfaces. These features will ensure the safe operation of the machine and provide peace of mind for your operators.

Maintenance and Support: Consider the maintenance requirements of the wire saw and the level of support provided by the manufacturer. Look for equipment that is easy to maintain and comes with reliable customer support. This will help minimize downtime and ensure that your operations run smoothly.

By carefully considering these factors, you can choose the right granite wire saw that meets your specific needs and maximizes your cutting efficiency. Remember, investing in high-quality equipment will ultimately lead to better results and increased productivity.

Maintenance and Safety Tips

When it comes to using granite wire saws, proper maintenance and safety practices are crucial for ensuring optimal performance and minimizing the risk of accidents. Here are some expert tips to keep in mind:

Regular Cleaning and Lubrication: Clean the wire saw regularly to remove any debris or slurry that may accumulate during cutting. Lubricate the machine's moving parts to prevent friction and ensure smooth operation.

Inspect and Replace Worn Parts: Regularly inspect the wire saw for any signs of wear or damage, such as worn-out diamond beads or loose wire tension. Replace any worn parts promptly to maintain cutting efficiency and prevent accidents.

Proper Wire Tension: Maintain the correct tension of the wire to ensure precise cutting and prevent wire breakage. Follow the manufacturer's guidelines for adjusting and maintaining the wire tension.

Safety Gear and Training: Always wear appropriate safety gear, including goggles, gloves, and protective clothing, when operating a granite wire saw. Ensure that operators are properly trained in the safe use of the equipment to minimize the risk of accidents.

Secure Work Area: Create a secure work area by marking off the cutting zone and keeping bystanders at a safe distance. Secure the workpiece firmly to prevent movement during cutting.

Monitor Cutting Conditions: Regularly monitor the cutting conditions, such as wire speed, feed rate, and water flow. Adjust these parameters as needed to optimize cutting efficiency and prevent overheating.

Remember, proper maintenance and adherence to safety protocols are essential for maximizing the lifespan of your granite wire saw and ensuring the safety of operators. By following these tips, you can achieve efficient and safe cutting operations with your granite wire saw.

Contact us, you will get more than what you see.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-18030177538

-Email: VIP@zliontools.com

-Web www.zliontools.com

-

Online service

-

Official wechat account

-

QQ:844389055

-

E-mail:VIP@zliontools.com

Online Message

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.