- Application

- For Concrete For Stone For Dekton/Ceramic For Glass Others

- Hot Products

-

ZL-123W Resin Flexible Hand Sandpaper Diamond Sanding Sheets for Hard Alloy Surface and Edge Grinding

ZL-37HSB Flexible Best Hand Sanding Block for Hard Metal & Plastics Surface Grinding and Trimming

ZL-123T 4 inch Diamond Dry Polishing Pad for Stone Marble Polishing

ZL-37C Electroplated Diamond Hand Polishing Pad for Ceramic Stone Glass Edge Polishing

ZL-EB Flexible Sanding Diamond Abrasive Belt for Glass Automatic Processing Machines

ZL-16KP Diamond Resin Bond Wet Polishing Pads for Concrete Grinding

ZL-16AD Resin Bonded Floor Polishing Pads-Dry Use

ZL-123M Metal Bond Floor Polishing Pad

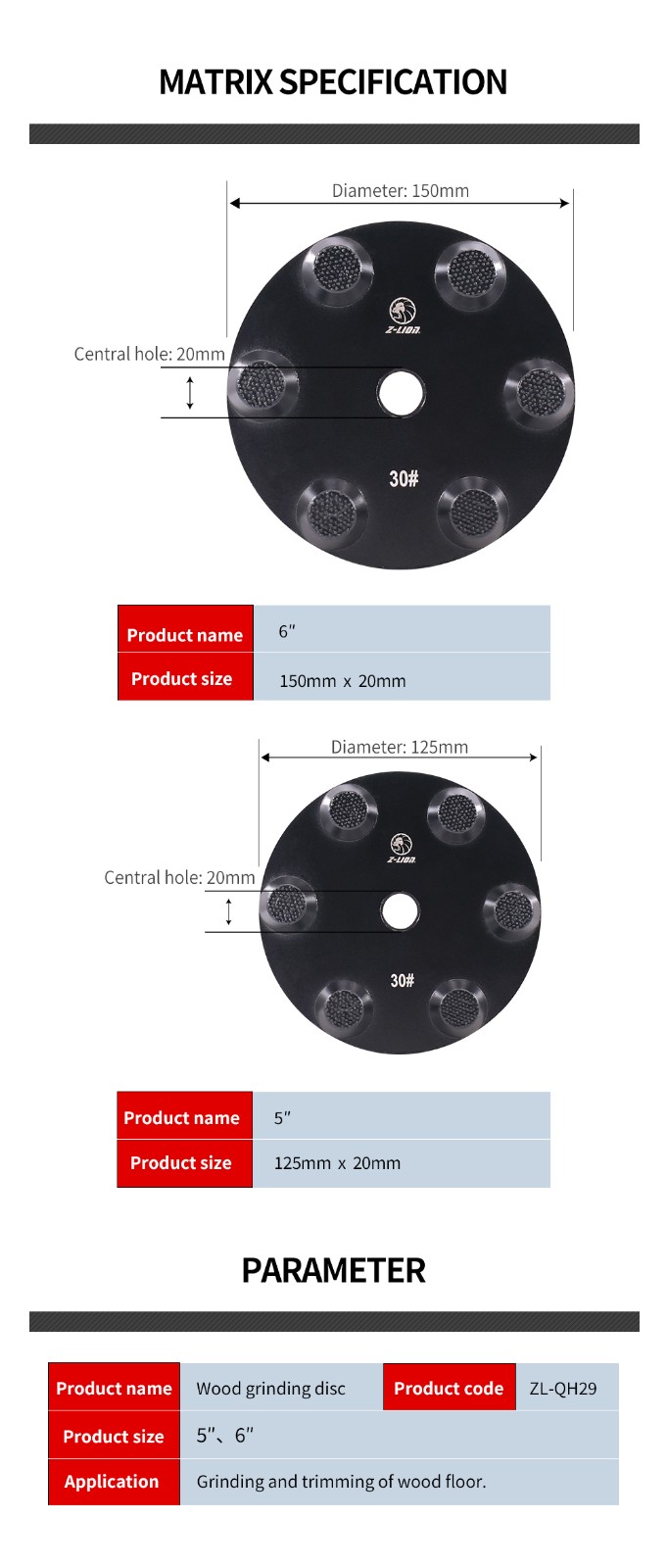

ZL-QH29 Wood Grinding Disc

ZL-QH29 Wood Grinding Disc for Wood Floor Trimming with Metal Segment Design

Fine workmanship, aggressive and wear resistant. Grinding and trimming of wood floor. Grinding and trimming of wood floor.

Advantage:

1.With selected diamond of high hardness, make grinding more easy.

2.Effective heat dissipation, grind smoothly, obvious effect.

3.Aggressive and no falling of segment, strong grinding force.

4.No deformation of matrix, no trembling, strong stability.

Product code: ZL-QH29

Product size: 5”, 6”

A Comprehensive Guide to Wood Grinding Discs

Introduction

Welcome to our comprehensive guide to wood grinding discs! If you're looking to enhance your woodworking projects and achieve professional-level results, then you've come to the right place. Wood grinding discs are essential tools for shaping, grinding, and cutting wood, allowing you to unleash your creativity and bring your woodworking ideas to life.

In this guide, we will explore the world of wood grinding discs, providing you with valuable insights and information to help you make informed decisions. We will delve into the different types of wood grinding discs available, their specific uses and applications, and how to choose the right disc for your woodworking needs. Additionally, we will share important safety tips to ensure that you can work with wood grinding discs confidently and without any risks.

Whether you're a seasoned woodworker or just starting out, this guide will serve as your go-to resource for all things related to wood grinding discs. We understand the importance of having the right tools for the job, and with the knowledge and guidance provided in this guide, you'll be able to maximize the potential of your angle grinder and achieve outstanding results in your woodworking projects.

So, let's dive in and discover the world of wood grinding discs together. Get ready to take your woodworking skills to the next level and unlock endless possibilities with these versatile and powerful tools.

Understanding Wood Grinding Discs

Wood grinding discs are essential tools for shaping, grinding, and cutting wood materials. These discs are designed to attach to angle grinders, providing versatility and efficiency in woodworking projects. Understanding the different types and uses of wood grinding discs is crucial for achieving the desired results.

Wood Carving Discs: These discs are specifically designed for carving intricate details and shaping wood. With their sharp teeth and convex shape, they allow for precise and accurate carving.

Flap Discs: Flap discs are versatile tools that can be used for finishing and shaping wood surfaces. They come in different grits, allowing for varying levels of smoothness and surface preparation.

Wire Wheels: Wire wheels are ideal for removing rust, paint, and other coatings from wood surfaces. They consist of wires attached to a circular base and are available in different thicknesses and bristle types for different tasks.

Diamond Cutting Discs: Diamond cutting discs are the sharpest and most durable among wood grinding discs. They are designed for cutting hard and resistant materials like granite and can be used for both dry and wet cutting operations.

Polishing Pads: Polishing pads are used to achieve a shiny and finished surface on wood. They come in various shapes and materials, allowing for different finished looks.

By understanding the different types of wood grinding discs and their specific uses, woodworkers can choose the right disc for their projects. It is important to consider factors such as the material being worked on, the desired finish, and the speed required for the task.

Safety should always be a priority when using wood grinding discs. It is recommended to wear appropriate safety gear, such as goggles and gloves, to protect against flying debris. Additionally, following proper usage guidelines and maintaining the discs in good condition will ensure safe and effective woodworking operations.

Types of Wood Grinding Discs

When it comes to wood grinding discs, there are several types available on the market, each designed for specific applications. Understanding the different types can help you choose the right disc for your woodworking needs. Here are some common types of wood grinding discs:

Flap Discs: These discs are made of overlapping abrasive-coated flaps and are ideal for finishing and shaping wood. They can remove rough edges, smooth out imperfections, and create smooth, rounded edges.

Carbide Discs: Carbide discs are known for their durability and long-lasting sharpness. They are designed for heavy-duty stock removal and shaping tasks. These discs are often used for rough shaping and sculpting wood.

Sanding Discs: Sanding discs are commonly used for smoothing and refining wood surfaces. They come in various grits, allowing you to achieve different levels of smoothness. Lower grit discs are more aggressive and remove material quickly, while higher grit discs provide a finer finish.

Grinding Wheels: Grinding wheels are typically used for more aggressive stock removal and shaping tasks. They are made of abrasive particles bonded together and are available in various shapes and sizes. Grinding wheels are suitable for removing large amounts of material quickly.

Diamond Discs: Diamond discs are extremely durable and are designed for cutting and grinding hard materials like wood with embedded nails or concrete. They have diamond particles embedded in their surface, providing excellent cutting performance and longevity.

When choosing a wood grinding disc, consider the specific task you need to accomplish and the type of wood you are working with. Different discs have different levels of aggressiveness and are suitable for different applications. It's important to select the right disc to achieve the desired results efficiently and effectively.

Remember to always follow safety precautions when using wood grinding discs, such as wearing protective gear and using proper techniques. By understanding the different types of wood grinding discs and their applications, you can make informed decisions and achieve excellent results in your woodworking projects.

Choosing the Right Wood Grinding Disc

When it comes to choosing the right wood grinding disc, there are a few key factors to consider. By understanding these factors, you can ensure that you select the disc that will best meet your needs and provide optimal results.

Disc Type: Wood grinding discs come in various types, including abrasive discs, diamond discs, flap discs, and wire wheels. Each type has its own unique features and advantages. For example, abrasive discs are ideal for cutting and shaping wood, while diamond discs are best for grinding and polishing. Consider the specific task you need to accomplish and choose the disc type accordingly.

Grit Size: The grit size of the disc determines its coarseness or fineness. Discs with lower grit numbers are more coarse and are suitable for rough shaping and removing material quickly. On the other hand, discs with higher grit numbers are finer and are ideal for smoothing and polishing wood surfaces. Consider the level of refinement you require and select the appropriate grit size.

Disc Size: Wood grinding discs come in various sizes, typically ranging from 4 inches to 7 inches in diameter. The size of the disc you choose should depend on the size of your angle grinder and the scale of your woodworking project. Larger discs are generally more suitable for larger angle grinders and larger-scale projects.

Quality and Durability: It is essential to choose a high-quality wood grinding disc that is durable and long-lasting. Look for discs made from high-quality materials that can withstand the demands of wood grinding. Reading customer reviews and selecting reputable brands can help ensure that you choose a disc that will provide reliable performance.

By considering these factors and selecting the right wood grinding disc for your specific needs, you can achieve efficient and effective results in your woodworking projects. Remember to always prioritize safety and follow the manufacturer's instructions for proper use and maintenance of the disc.

Safety Tips for Using Wood Grinding Discs

When it comes to using wood grinding discs, safety should always be the top priority. These discs are powerful tools that can cause serious injury if not used properly. Here are some important safety tips to keep in mind when using wood grinding discs:

Wear Protective Gear: Before you start using a wood grinding disc, make sure you are wearing the appropriate protective gear. This includes safety goggles to protect your eyes from flying debris, gloves to protect your hands, and a dust mask to prevent inhaling wood particles.

Check the Disc: Before using a wood grinding disc, inspect it for any signs of damage or wear. Discs that are cracked or worn down should not be used, as they can break during operation and cause injury. Always use a disc that is in good condition.

Secure the Workpiece: When using a wood grinding disc, it is important to properly secure the workpiece. Make sure it is firmly clamped or held in place to prevent it from moving or shifting during operation. This will ensure a more stable and controlled grinding process.

Use the Right Speed: Different wood grinding discs have different recommended operating speeds. Make sure you are using the disc at the correct speed for the specific task. Operating at too high of a speed can cause the disc to overheat and wear down quickly, while operating at too low of a speed can result in inefficient grinding.

Maintain Control: When using a wood grinding disc, always maintain a firm grip on the tool and keep it steady. Avoid applying excessive pressure or force, as this can cause the disc to bind or kickback. Use smooth and controlled movements to achieve the desired grinding results.

Take Breaks: Grinding wood can generate a significant amount of heat and dust. To prevent overheating and to minimize exposure to wood particles, take regular breaks during extended grinding sessions. This will allow the disc to cool down and give you a chance to clean up any accumulated dust.

By following these safety tips, you can ensure a safer and more effective experience when using wood grinding discs. Remember to always prioritize safety and take the necessary precautions to protect yourself and others.

Contact us, you will get more than what you see.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-18030177538

-Email: VIP@zliontools.com

-Web www.zliontools.com

-

Online service

-

Official wechat account

-

QQ:844389055

-

E-mail:VIP@zliontools.com

Online Message

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.